Switched Careers From Marketing to Electronics

After 12+ years in marketing, I now have 2+ years of cable assembly experience, on target for a distinction in Electrical Engineering (HNC), repurposed 250+ electronics for resale and developing skills every day. I am also selling my domain; Avionics.co.uk!

About Me

Spent a decade learning online ad strategy, gaining Google certifications and all-round ‘digital marketing’ skills, but Covid helped me realise it wasn’t too late to pursue something more meaningful and in-line with my passions, to take things apart and try to put them back together.

Naturally curious, creative, and love to push my capabilities. Calm under pressure and aim for right first time, taking pride in my work and leveraging fine motor skills, aptitude, and a willingness to fine-tune skills, whether hand tools or techniques. Thrive under the right mentorship and guidance.

I have always been interested in electronics but thought it was too late to change careers, I am now 35 and in the last 2-3 years I have proudly developed:

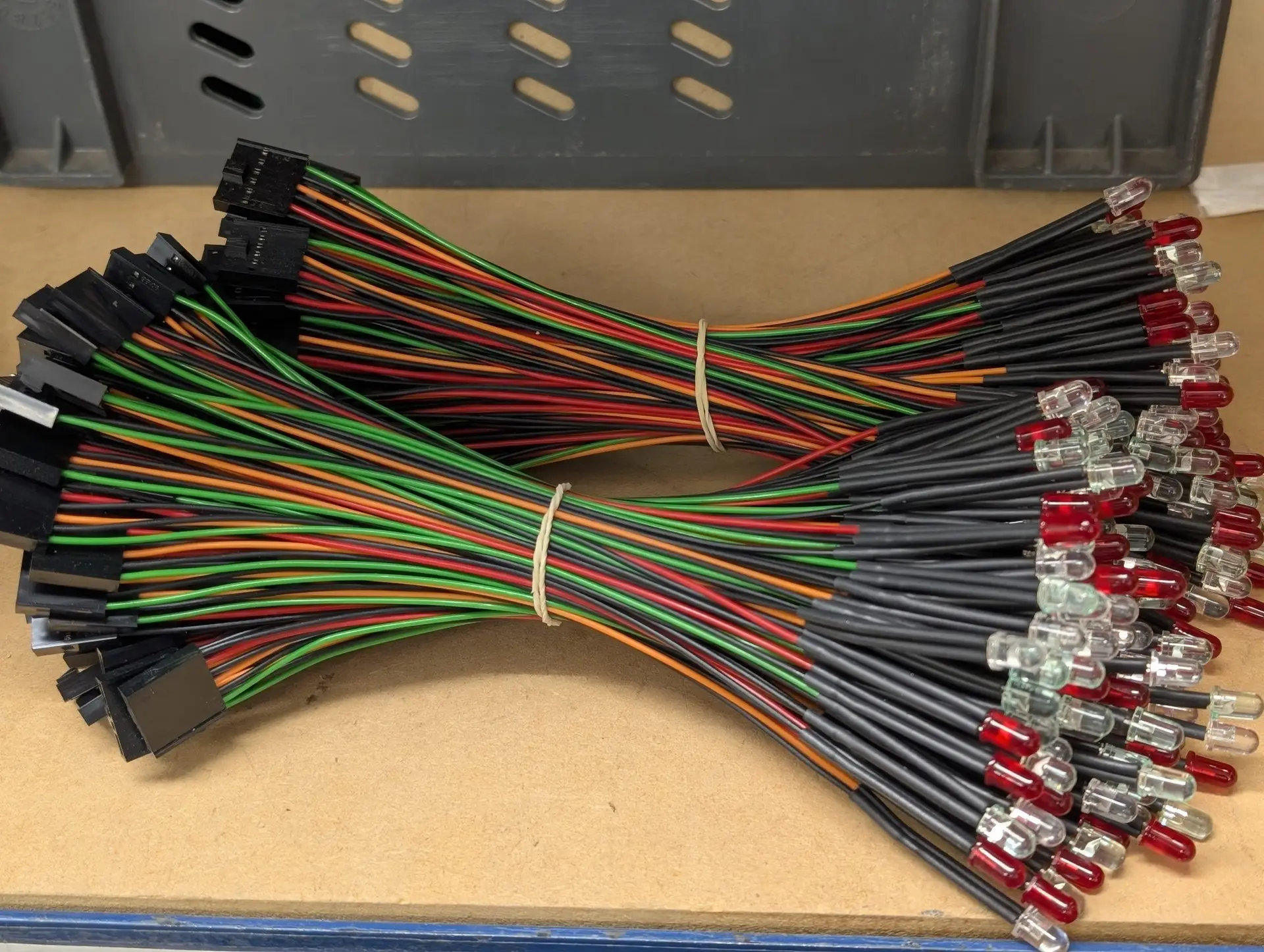

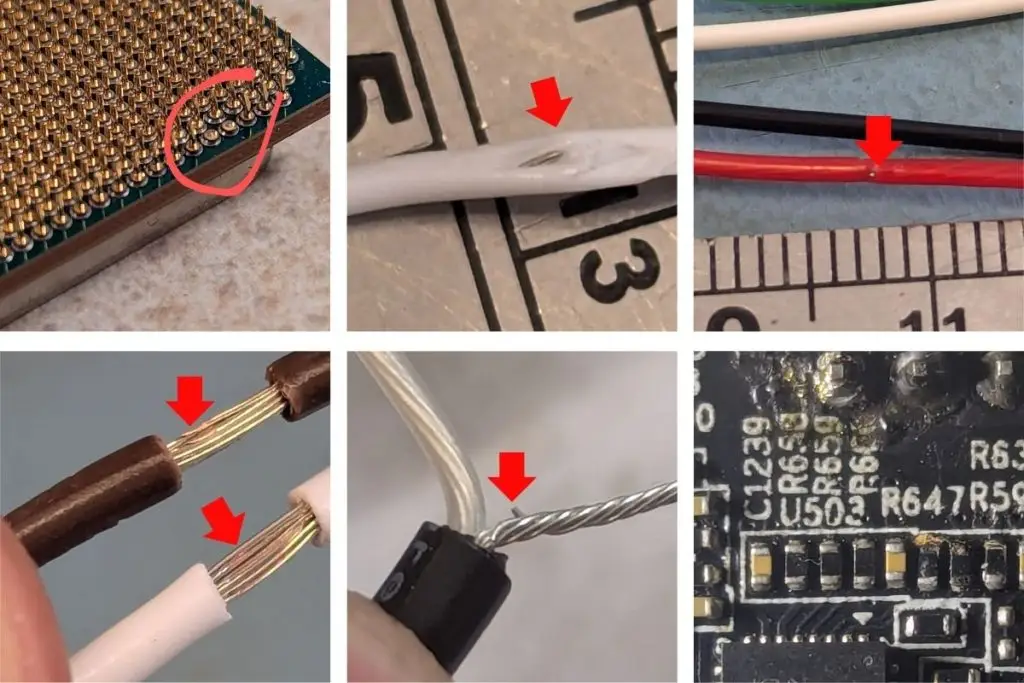

- Soldering – including some through-hole, surface mount, D-sub and basic splices etc.

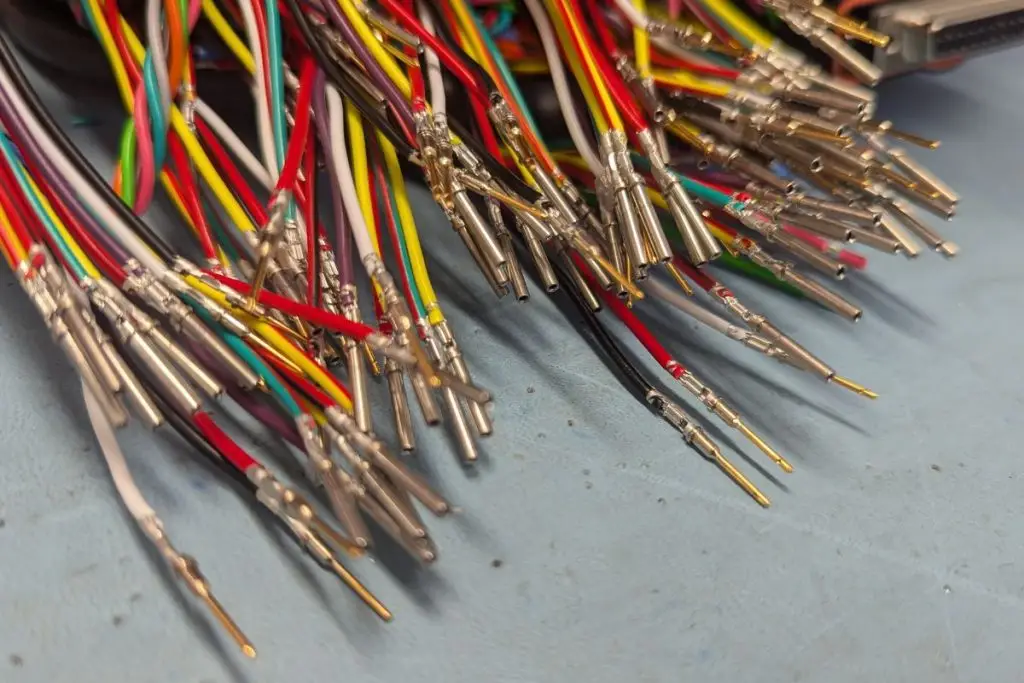

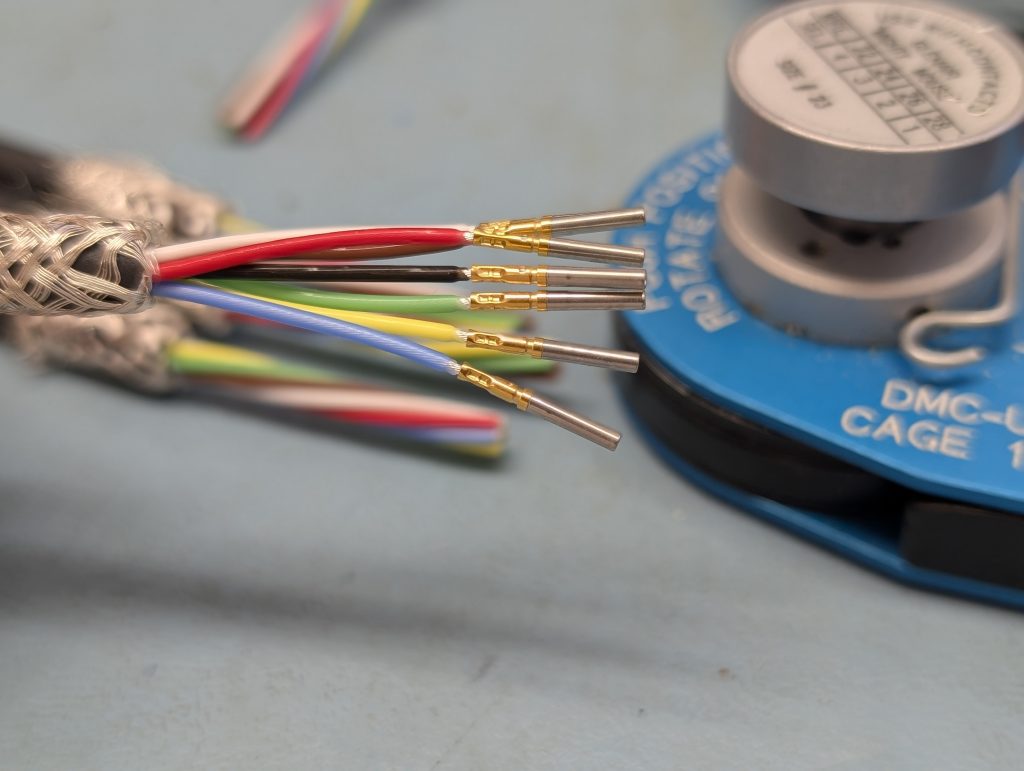

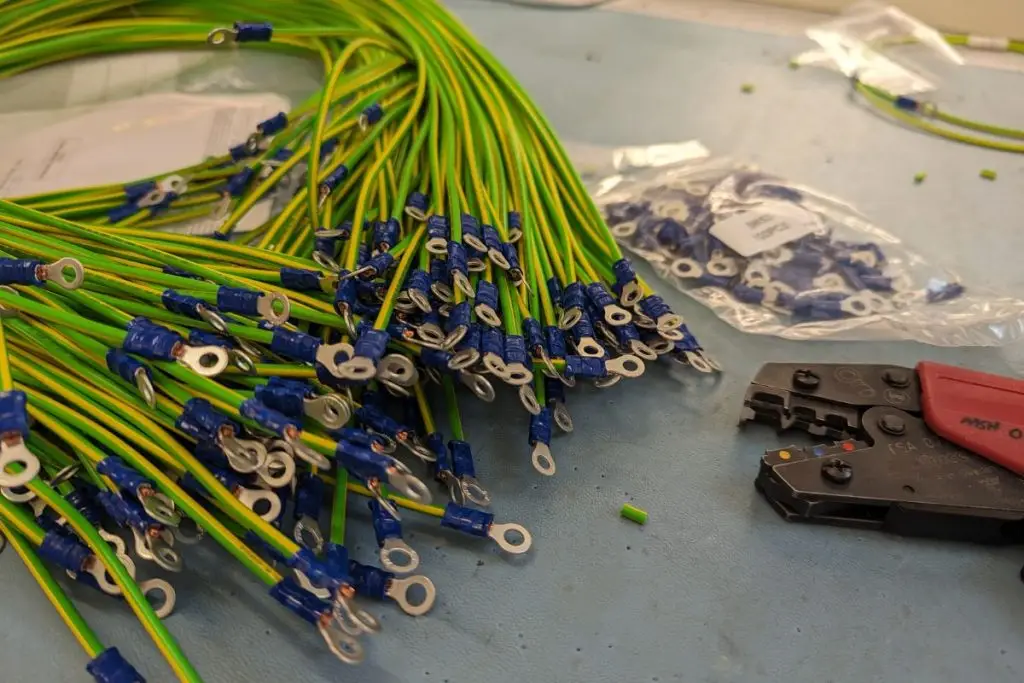

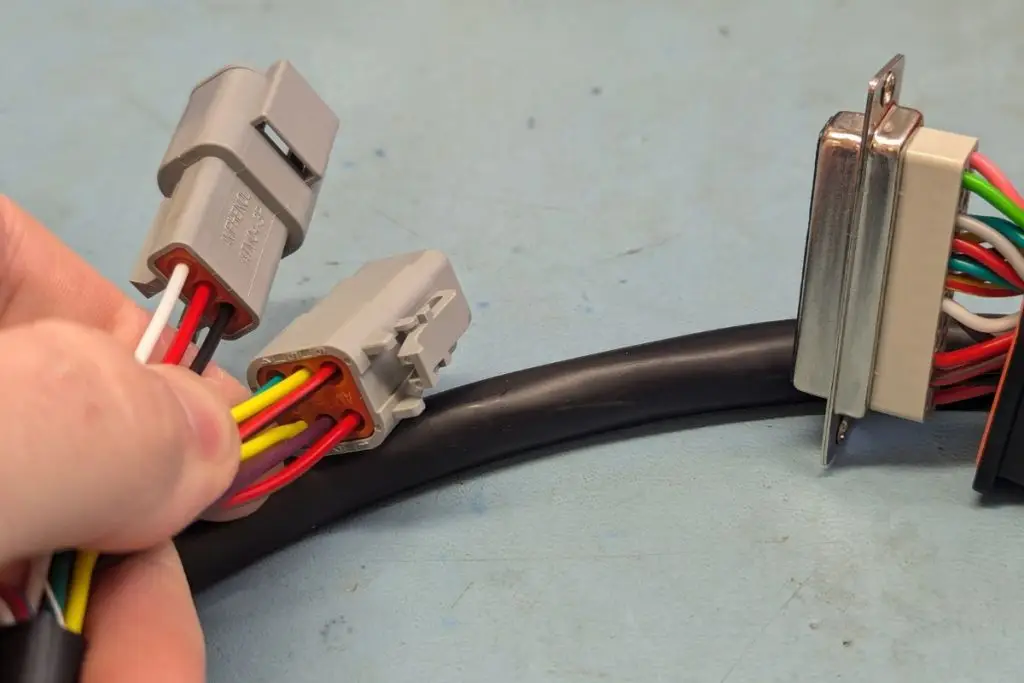

- Crimping – wide range of crimp types and tools including: ferrules, JST, molex, D-sub, circular pins

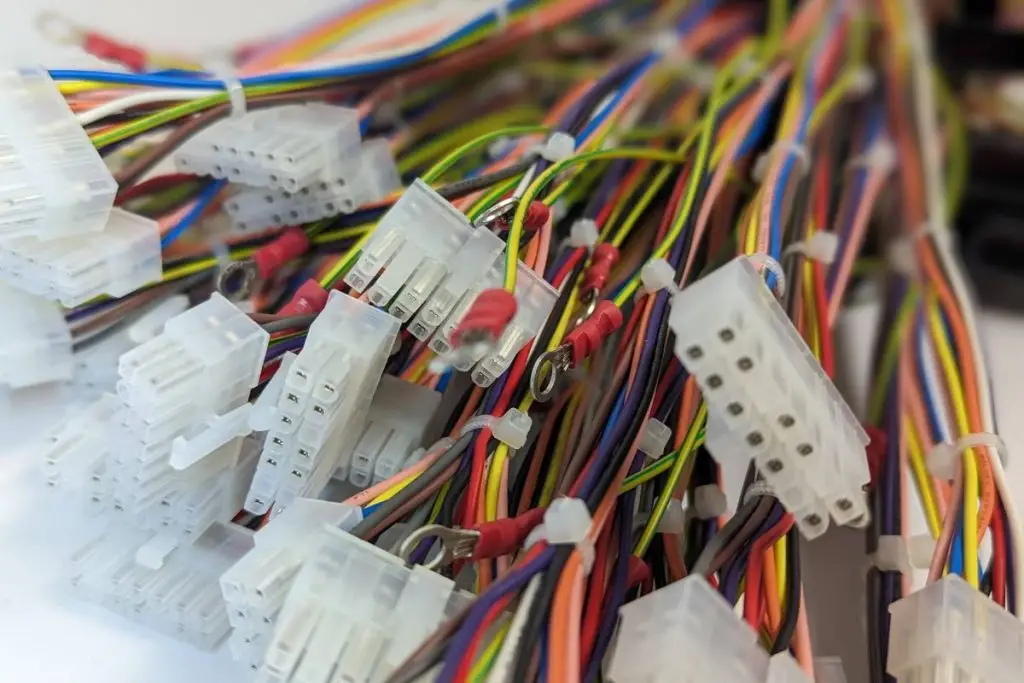

- Cable assembly – connectors including MIL type, following pinouts and diagrams, heatshrinking, branching and inspection.

- Electronic assembly – familiarity with concepts like grounding, some basic visual inspection.

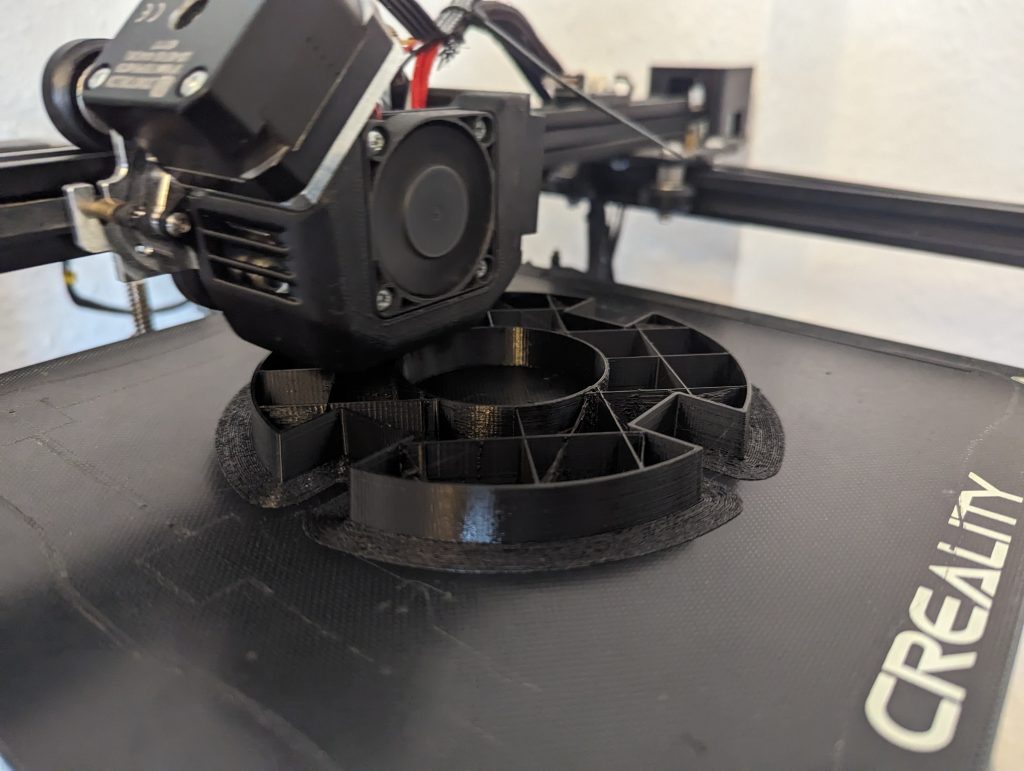

- Fusion 360

- Arduino

- 3D Printing

I am self-funding a HNC in Electrical and Electronic Engineering, which I am half way through and on target for a distinction.

Journey So Far

I had always built my own computers or repaired laptops. This is where I gained hardware diagnostic and electronic assembly experience. I found a lucrative niche in buying broken PCs and learnt basic electronic repairs. Over the last 3 years I have continued this and now sitting at around 400~ items sold with 100% feedback.

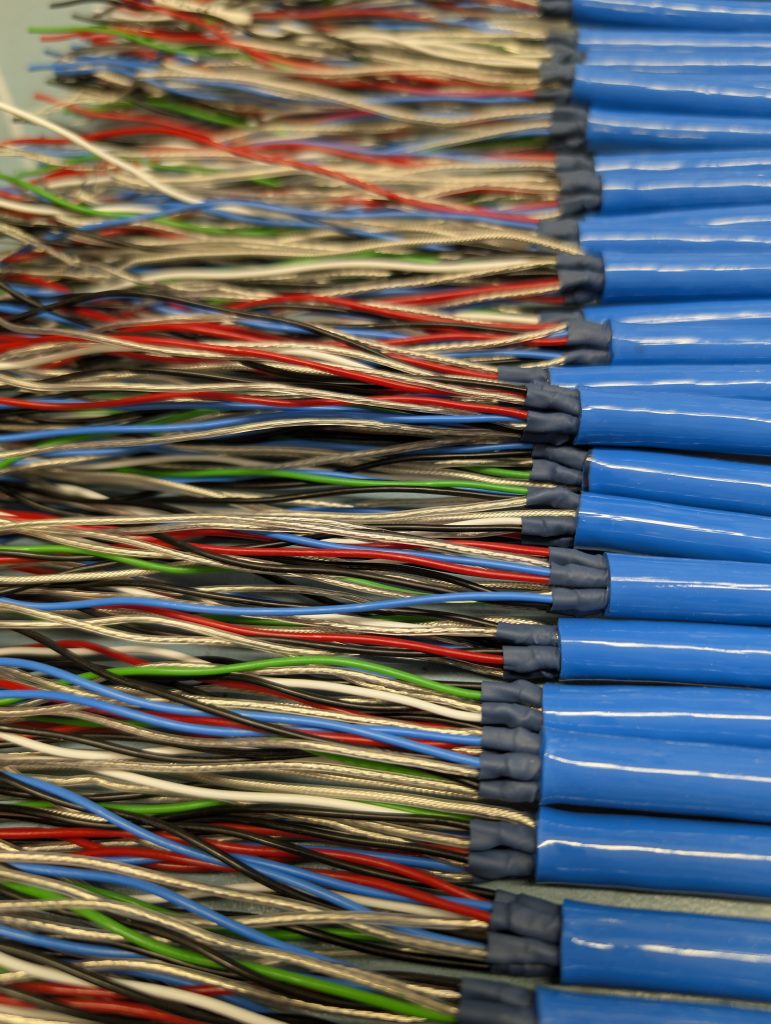

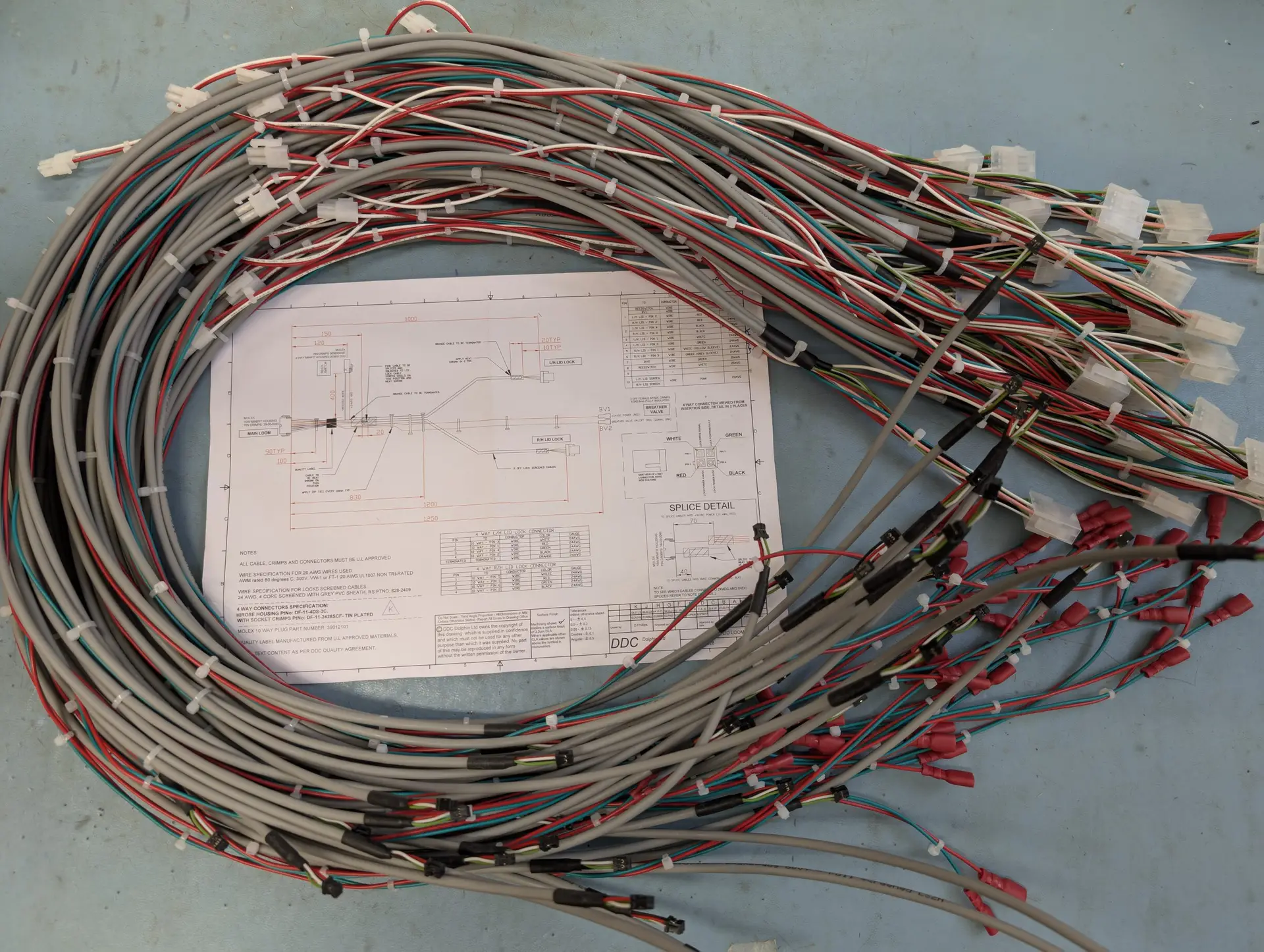

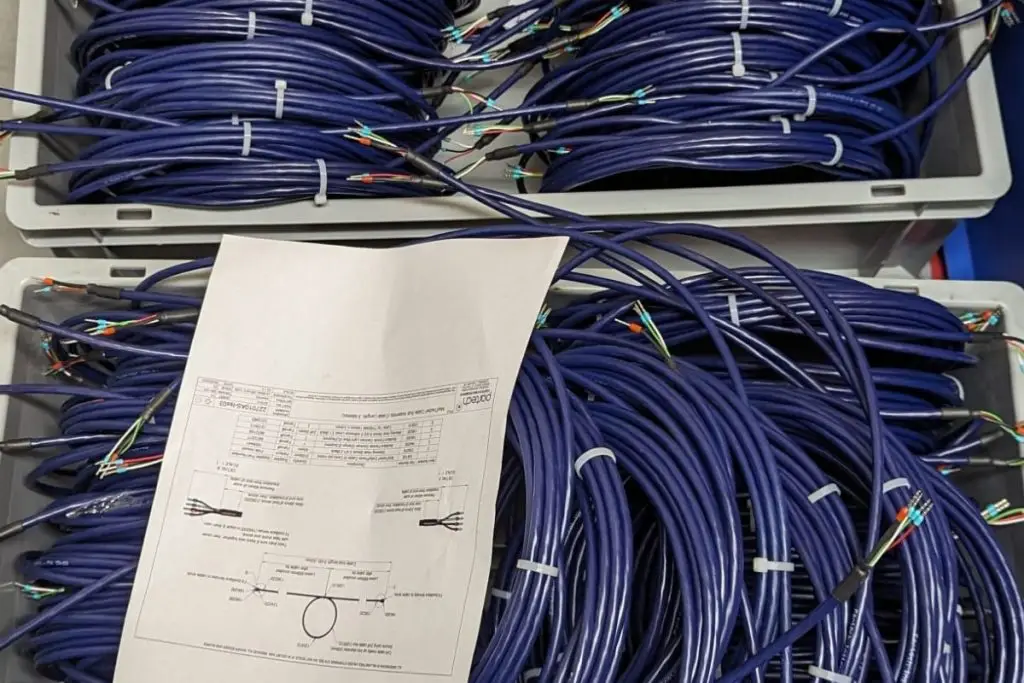

Cable Assembly was my first break into the career path. Coincidentally I approached a local firm in the hope they could help me solder pins onto broken AMD processors I was buying and selling on eBay. To my surprise I was offered a job and didn’t look back. That journey has taken me from never touching wire strippers or crimpers, to now competent at a wide-range of wiring tasks to IPC 620 standards and class 2/3 assemblies, from automotive to defence.

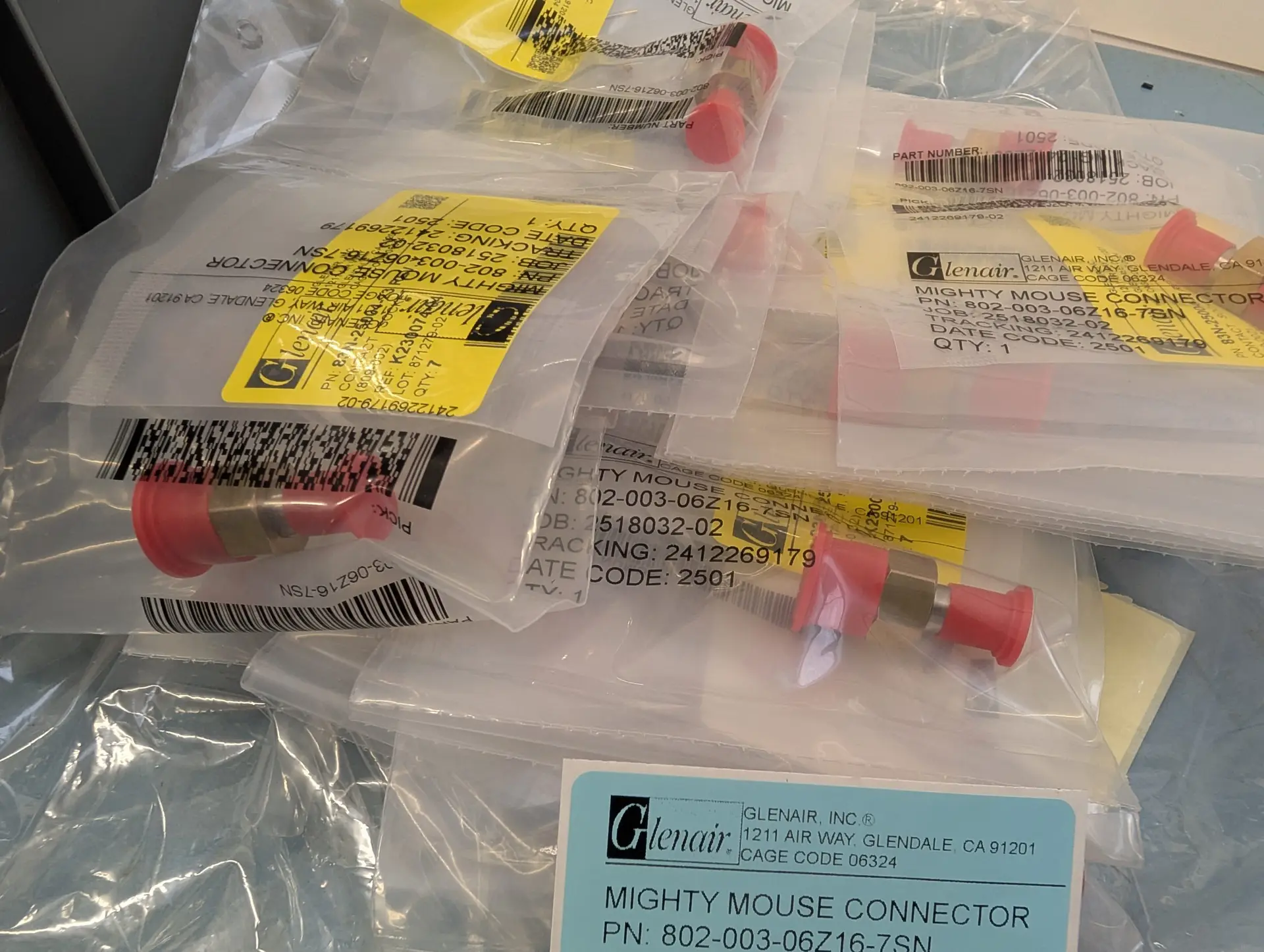

Experience with a wide range of crimp tools for crimp and connector types including Circular, Dsub, RF and families including Amphenol, Deutsch, Glenair, Molex. I am familiar with ISO9001 practices and follow a quality first mindset, I am also self-teaching soldering to J-STD-001 and own the physical handbook, eventually aiming to gain my IPC certifications.

NDT & Visual Inspection

Once I am familiar with a product I tend to spot deviations in manufacturing or erroneous details and reject criteria, from crushed, severed or scraped cores to detached or damaged components. Though limited exposure to PCB, I am familiar with delamination, conformal coating, burning and trace damage. As well as basic continuity testing with a multimeter.

Cable Assembly

I enjoy complex cable assemblies and take great pride in completing these tasks to exact specifications and IPC standards. Taking into account every stripped wire and termination, I temper variability by adjusting to nuance within the sub assemblies.

Electronic Assembly

Primarily PC hardware, I have assembled dozens of computers and used benchmark software to troubleshoot faults. Analysing base level performance, no outputs, monitor stability, temperatures and ensure things like 3V, 5V, 12V power rails are reading the correct voltages.

What I Offer

Willingness to perform each task to 100%